一. The choice of grain rubber adhesive

The use of rubber adhesives, Feixiang recommended users choose neoprene adhesive technology.

二. Bonding method

1 Coating roller surface processing - before coating adhesive, should use sandpaper or organic solvent such as gasoline, toluene wipe roll surface, remove rust and oil etc., on the surface of the adhesive.

2 Besmear brushs tool, besmear to choose the appropriate tools scraper, scraper, brushes, etc.Because for cylindrical roller surface, if besmear to brush, brush besmear after should reoccupy scraper, scraper coating evenly.

3 Adhesive coating, coating method has two kinds: one is from a brush head to both ends of the rolls, one operator can;Another central from the roll to besmear to brush, both ends for two people operation, two methods are covered with the adhesive surface.The process should pay attention to besmear to brush to the same direction, avoid besmear to brush back and forth, in case you have bubbles, thereby ensuring the uniformity of coating, avoid by all means lack of glue and thickness unevenness.

For neoprene adhesive strength is high, early good viscous force, on the premise of guarantee the stick relay, had better use the single side glue, namely besmear to brush roller surface, need not besmear brushs rough surface rubber adhesive.

4 Adhesive is dry, because neoprene adhesive is depend on the solvent volatilization and curing can reach the effect of adhesive, in order to get the best bonding effect, have to pass air buy, after besmear to brush the glue for adhesive with good infiltration of bonding time, get to form uniform adhesive binding layer.If the residual solvent air buy enough time, will produce bubbles and loose phenomenon, affect the bonding effect, may cause serious matte rubber swelling or with roller slippage;If air buy time is too long, solvent evaporation too dry, the film will lose adhesion, coating adhesive after drying time is not glue the hand, namely the temperature 10-15 minutes, according to the season, choose a different time, auxiliary can use hair dryer to dry in the winter.

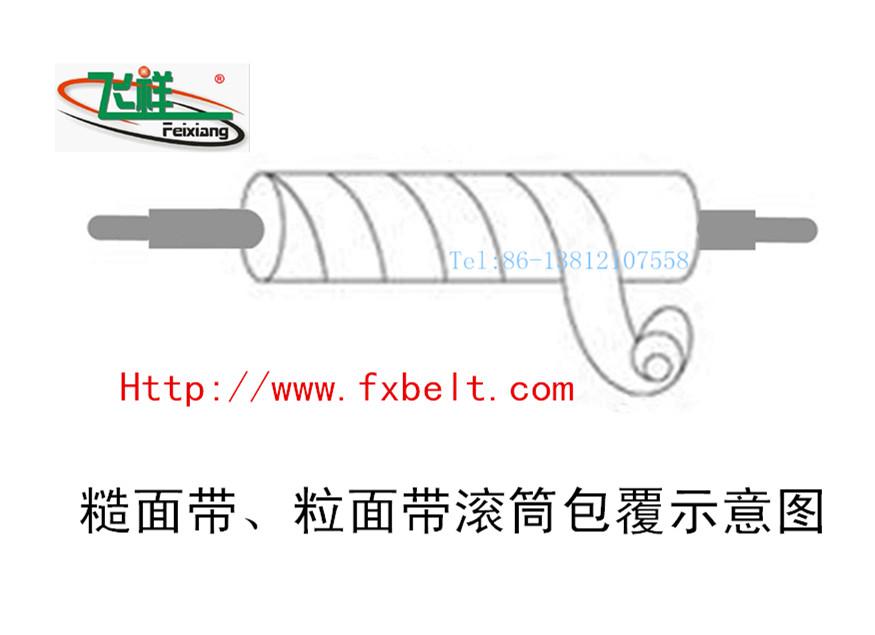

5 Tape package rough, rough tape package, should first take rough head cut at an Angle, from one end of the roller, the rough surface of rubber is compact and uniform juggle package around the side pressure on the roll, with clip or screw fixed on both ends, after the package to trim the tail, belt and the roller edge level, process as shown.

Room temperature curing adhesives, only under the condition of a certain pressure, time and so on to make the glued to achieve the best adhesion.Therefore, matte rubber requirements have a certain tension in the surrounding the process, make the rough surface with pressure on the roll.After the rough bag around, room temperature curing takes about 12 hours, can drive use, after three days will reach the highest bonding strength.

6 Note - for neoprene adhesive solvent adhesive, solvent volatilization excessive can cause adhesive thicken, sometimes difficult to besmear to brush, so seal should be paid attention to in use process, if appear thickening phenomenon, can use gasoline or dilute acetic acid ethyl ester, stir well after use.

Besmear brushs tools used in the application of gasoline or ethyl acetate cleaned in time, arrange another time touse.

Common problems and solutions

Common problems | Cause | Processing method |

Rubber and iron roll off |

Too little or too dry coating adhesives; | 1、Adhesive coating too much or too little or volatile dry, should be moderate and with non-stick hand advisable; 2、Check whether the glue is more than the period of validity; 3、Check whether the glue is too thick, so should add a small amount of ethyl acetate dilute stir well before use; |

Shortly after the computer pattern smooth rubber surface | Rubber and iron roller sticky rickety,have slip.phenomenon;Device adjustment is bad, winding roller and cloth roller malposition | 1.Rough zone after being solidified, stick to the roller with the hand push its edges, see if there is a sliding phenomenon,otherwise should be glued down again 2.If tape computer time is not long pattern is smooth, should check the take-up roll and the position of the cloth roller is parallel;Both ends of the bearing are eccentric phenomenon;Machine lubrication is normal, found that the problem should be timely adjustment; 3.According to the provisions of warranty equipment on a regular basis. |