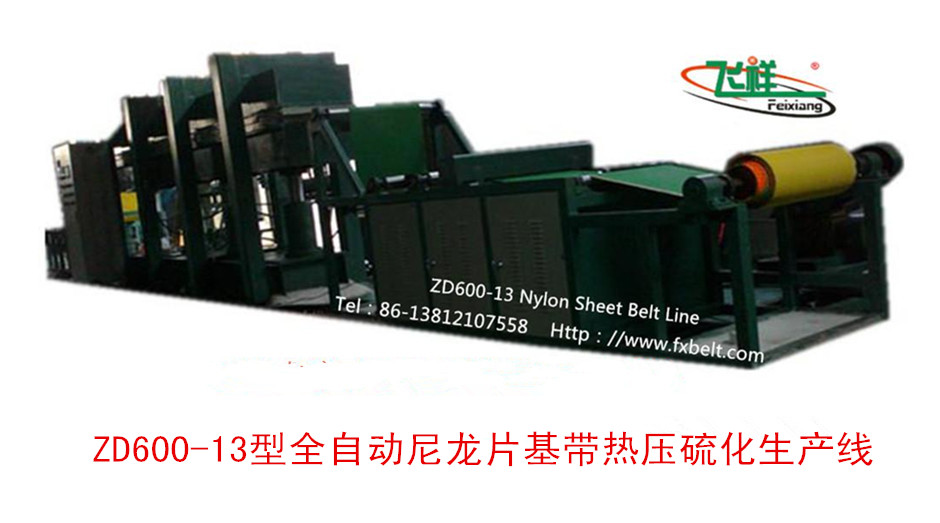

ZD600- type nylonbelt hot-pressing production line——is specialized in producing nylon film base belt embryo equipment.After many years of continuous improvement in the production practice and technical innovation, the production line has the advantages of environmental protection, energy saving, consumption reduction, is a collection of mechanical, electrical, hydraulic, PC computer control automatic production line, the line is for internal quality and external quality of nylon film base belt, and there were a sharp rise in labor productivity, 1-1.5 mm belt production, especially for quality effect is particularly significant, changed the traditional system with process thin belt belt carcass uneven defect.

Equipment has the following several parts:Electrical control system (using industrial computer PLC control, touch screen), rolling system, test system, automatic belt body pressure system, curing system, heating system, cooling system, hydraulic system, vulcanization hot platen assembly, automatic belt tensioning system, winding, etc. Technical parameters:

Equipment has the following several parts:Electrical control system (using industrial computer PLC control, touch screen), rolling system, test system, automatic belt body pressure system, curing system, heating system, cooling system, hydraulic system, vulcanization hot platen assembly, automatic belt tensioning system, winding, etc. Technical parameters:

The length of the plate vulcanizing equipment:5m

Two plate spacing:160 mm

Curing equipment flat area:5000mm*620mm

Vulcanization equipment total pressure:2500KN

The heating medium:heat conduction oil, steam

Apply to the thickness of the baseband:1mm∽6mm

Embryo maximum width shall apply:600mm

Nylon belt type shall apply:Double-sided cloth、nylon tape as well as the automatic sulfide belt

Equipment installation length:about 9∽13.5 m

Total power equipment:14KW

Winding diameter:Ø1000 mm

The system working pressure:6.3∽25MPa