一. Belt selection

When choosing belt model, user should according to the power to choose the right specifications of the tape belt transmission, more experience by adopting the analogy method selection, the user can seek advice if necessary Jiangyin Feixiang technology co., LTD. Technical personnel, at the same time also should pay attention to all kinds of tape for minimum pulley wheel diameter.

二. Belt to determine the actual size

1.Nylon film base belt compared with nylon short film base dragon belt size is easy to measure;

2.The determination of nylon film base dragon belt size,In addition to according to the calculation results in advance, but also depends on the transmission system of tension adjusting device of the actual amount adjustment.Generally the dragon with the installation of the elongation of 1.5-2.5%, if the amount of tension device to adjust equipment can meet this requirement, can according to the minimum length connector (calculate) circumference;If the amount of tension device to adjust equipment is small, can't satisfy the transmission power at the beginning of the tension, short would then take necessary preliminary measures to bring the dragon than size truncated some calculation, concrete the truncated quantity depends on the amount can be adjusted.

For example, a dragon with a 20000 mm long, calculate elongation is 2%, namely after the tension adjust quantity should be 400 mm.But the amount of the adjustment of the tensioning device is 150 mm, the tension device to the end, the dragon with capacity of 300 mm, maximum tensile elongation is 1.5%, can not meet the requirements of tension.Therefore, can be the dragon with the length of the production for 19850 mm or 150 mm short, when took the dragon when loaded on the pulley (tension device in the most medial position), its elongation is 0.75%, and 1.25% of the amount of tensile elongation, which is 250 mm, can move outward through the tensioning device 125 mm to catch up on.Tension after tensioning device and 25 mm mobile content, namely 0.5% elongation allowance, so the belt can obtain the ideal installation elongation after the computer, so as to satisfy the requirement of the transmission power tension.

三 .Nylon belt storage security

1.Belt should be sealed in a special vacuum bags store under shade environment, and away from heat and light to take light put, in case the touch broken packing.

2.Belt storage space average temperature of 25 + 2 ℃, relative humidity 65 + / - 5% is good - to keep the fine performance of the tape.

3.Nylon film base dragon belt must be sealed in a special vacuum bags store away from light.Removal should be careful, in case the touch broken.When used to open the bag again.

4.Nylon baseband joint use of adhesive should be sealed cap tightly after use.

四. The installation of the belt

1.The installation of nylon belt

Baseband installed, install elongation can be counted on to tighten, and measured by tightening the belt after the actual spacing, such as: belt surface tension marker on spacing is 500 mm, if the installation of belt elongation is 2%, should be gradually tensioning belt mark distance of 510 mm.Uniform for belt tension, tension should be good flat belt manual rotation for several weeks, and fine-tune, until confirm the tensioning tag spacing requirements.

Belt when installation, equipment, if can adjust, can will take first round center distance to the minimum, and then put the belt on the pulley set tension slowly again.If the equipment can not adjust, and no tension wheel, belt production should be short, need clean cloth to protect belt when installation, in case of damage, when installation with the proper tool rotation pulleys while set of belt.With belt installed, the degree of tension should be appropriate, to ensure that the belt drive the required pretension.General experience belt tensioning degree with the thumb to press about 15 mm advisable.

2.The base with the installation of the dragon

(1).Before installation, please carefully check the belt specification and model, the minimum equipment belt wheel diameter flat belt to meet the use effect and longevity.

(2).Please make sure that the pulley parallelism, the dragon take when installation should guarantee the dragon to take all the driving spindle wharve, its diameter should be in the same plane.

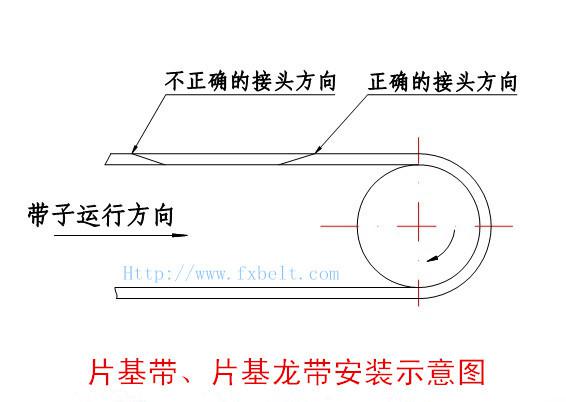

(3).Please follow with the surface of the belt running direction of arrow mark correctly installed, etc.

If any adjustment of the distance between the pulley device, install the dragon with very convenient;If not, when installation should be old cloth pad on the edge of the pulley or the old belt, to prevent the broken belt, and should turn the pulley and the set of dragon belt.For dragon belt is short, with the help of adjustable pitch device, can use homemade improvised entrainment device.With a long old dragon with port belt (leader) sets out, use entrainment device in the appropriate position are clamped together;Will take port installed to the wheel to regulate, activates the controllable pitch stretching flat belt to a new port to adjust the original position, then, hold the entrainment device, will adjust the wheel back in situ, new take port set on it;Loosen the entrainment device, take lead with can.

Dragon belt is short, the transmission system and no adjust device, wet can adopt appropriate measures of growth for the dragon with elongation amount after installation.

(4).Dragon belt tensioning

Pre tensioning——On the dragon with a surface tension marks spacing is 500 mm.Such as the dragon with standard use elongation is 2%, gradually with the tensioning dragon - mark distance of 510 mm.Segmented tensioning the effect will be better: the first step tensioning elongation two-thirds of the dragon with stretch up to standard idle for 15 minutes, uniform tension: then tension to the standard 2% elongation, 15 minutes idling balance tension.In order to make the dragon with uniform elongation, tension should be good dragon belt rotating weeks, confirm the tensioning mark spacing is in line with the requirements.

Film base dragon belt is more sensitive to environmental humidity change, should make the workshop humidity remained stable.And should be according to humidity adjusting dragon belt elongation, generally every poor 10% relative humidity, should be 0.05 ~ 0.1% elongation.

五. Use the maintenance

1. Dragon with the use of the site temperature and humidity should be basically stable;If the places and preservation temperature, humidity is too large, is transported to use place, dragon belt should be used for 1 ~ 2 days later.

2. Dragon with good chemical resistance., but not resistant to strong acid, phenol, alcohol corrosion, please pay attention to in use.

3. Machine after leaking lubricating oil tainted with dragon, immediately stop will take plane and pulley surface wiping clean, otherwise it will reduce the transmission speed.For the dragon belt should be periodically wiping a 1 ~ 3 months.If a large area of the oil, can take dragon using hair brush dipped in warm water to wash, and then to dry.

4.Began to use new belt, attention should be paid to the operation of the belt position, if there are any abnormal, should be adjusted immediately.

5. Dragon with cross drive, it is best in cross inserted into the body of revolution, avoid direct friction between belt and belt.

6. Dragon belt as a result of long-term use, qu torsion fatigue or mechanical failure, etc., can cause local degumming stratification, once discovered immediately repair, otherwise will cause the entire belt early damage.

7. Dragon belt transmission, when change to take walk location may change, should pay attention to adjust in a timely manner.

8. Dragon belt transmission, because the belt is long, for some reason, may sometimes produce snaking phenomenon, in order to prevent the belt or easy to adjust the belt to go, general methods can not meet the requirements, can design activities under the roller hold belt edge.

9. Since the top and bottom layer of the belt for special synthetic rubber, the use of the normal temperature for 20 ~ + 100 ℃, good oil resistance, available to all kinds of ordinary scour catharsis.But should keep the belt carcass clean when using, should prevent and concentrated acid, phenol, acetone, esters and other organic solvents, inunction antiskid oil shall be strictly prohibited.

六.Nylon belt common problems and solutions

type | Questions | Cause | Processing method |

Nylon pieces of baseband | The belt deviation | 1.Axis is not parallel to the two pulleys | Correction |

2.Pulley drive or uneven surface of grease | To remove dirt or repair | ||

3.Deformations can occur in the operation of the belt | Further tension or replacement | ||

Sacrificing speed | 1.The belt loose | Tighten | |

2.The belt size long, length adjustment device are inadequate | To recalculate the size | ||

3.Minimum pulley is too small,the package is not tight, skid | 切换到灵活的皮带 | ||

The noise is big | 1.Pulley surface uneven, is flawed | Clean or repair | |

2.Improper operation caused belt surface damage | Check and repair | ||

3.Belt and pulley contact isn't good | Tighten | ||

4.Two pulley drive surface offset, causing a belt running deviation or edge grinding | Correction of pulleys, repair, flat belt injury |

七.Nylon base dragon with common problems and treatment methods

type | Questions | Cause | Processing method | |

Nylon film base with dragon | Of spindle speed is not up to requirements | All the speed of the spindle can not meet the requirements | 1.Driving wheel slip | Increase the tension of belt |

2.There are oil pollution on the belt | When wiping with working face, wipe clean not in tape | |||

3.Belt wheel diameter is not appropriate | To conform to the regulation of spindle speed pulleys diameter | |||

4.Tension is too large, and more than belt transmission capacity | Increase the tension of belt, check pressure wheel pressure into the dragon with depth, etc. | |||

The edge of the belt loose individual spindle speed can not meet the requirements | Loose contact between the edge of the spindle and belt weight shortage | Increase the belt tension Adjust the pressure wheel pressure into the depth of the, | ||

Part of the spindle speed can not meet the requirements | Wheel and belt of the contact force is not enough | ncrease the pressure of wheel depth, | ||

Wound yarn spindle head, load increase | Clear yarn, make the normal load | |||

Spindle bearings turn bad | Replace the spindle bearing | |||

Belt surface uneven or foreign body adhesive | Take the dragon surface wipe clean | |||

noise | The noise of the continuous | Belt surface is uneven | With 80 mesh sandpaper gently lapping dragon belt inside and outside surface, remove the bumps | |

There's a foreign body in ingot plate attached | Take wharve and dragon to wipe clean | |||

The noise of the periodic | Dragon belt joint dissection | Repair stripping parts Or switch to a new belt | ||

Individual place making noises | Part of belt surface becomes uneven | Find out the causes of uneven, change with neosaurus belt special severity Because rotary, check whether the spindle is undesirable and high fever | ||

Deviate belt, deviate or yarn twist to the converted | Dragon belt running not adjusted | Roller or the axis of the guide roller position adjustment | ||

Dragon belt on the pulley shaft to move, the "serpentuate" | Dragon belt running not adjusted | Roller or the axis of the guide roller position adjustment | ||

Spindle shaking too much | Check the spindle bearing, if you have any damaged, replace | |||

Belt wheel on a raised garden arc surface wear | To repair or replace the pulley wheel surface | |||

Spindle or roller malposition.Wheel surface convex arc center is not in the same level. | Correction of bearing surface level | |||