Nylon belt-- Applicable to metal processing of mechanical transmission and spinning weaving, printing, paper making, woodworking machinery and other industries, belong to the plane of high speed transmission belt, with the middle tier for nylon film base body, up and down surface covered with rubber, leather, cloth, etc.;With the thickness of the body is usually in the range 1-6 mm.Jiangyin Feixiang technology co., LTD. Through absorbing the domestic and foreign advanced system with technology, self-developed automatic chip baseband drum-type vulcanization hot pressing cooling line, baseband hot-pressing sulfide production line, automatic coating production line, automatic chip baseband joint machine equipment, the equipment production belt product has good stability, high strength;Nylon chip baseband than traditional canvas belt and triangle: anti-bending of strong tension, and high efficiency, low noise, long service life, etc.The following brief introduction from the following several aspects of baseband production technology and equipment:

1. Nylon belt production process

Nylon belt process of production need to experience the following processes - ingredients, mixing, mixing, tape calendering, adhesive curing, tape, glue, adhesive film base composite molding, hot pressing vulcanization cooling with embryogenesis, tape drive, joint grinding, cutting ring joint, such as trimming process to complete.

2. Nylon belt production equipment

1). ZD600-13 type automatic production line for nylon chip baseband hot--pressing sulfide (also called automatic line) - for nylon baseband hot-pressing sulfide production, is a special equipment for the production of nylon film base belt.This production line has the advantages of environmental protection, energy saving, consumption reduction, is a collection of mechanical, electrical, hydraulic, PC computer control automatic production line, the production line of nylon film base belt of internal quality and external quality and labor productivity have greatly ascend, full pressure in a state of continuous heating the marked characteristics of sulfide and cooling, correct changed the traditional plate vulcanizing press molding system with the disadvantages of the production process, the whole production line only one operator.

Feixiang brand nylon chip baseband hot--pressing sulfide automatic production line has the following ten parts: the electric control system, using industrial computer PLC control, touch screen), automatic rolling system, the belt body pressure system, curing system, heating system, cooling system, hydraulic system, vulcanization hot platen assembly, automatic belt tensioning system, winding, etc.

2). TJ600-13 baseband automatic coating production line, used for nylon film base glue, tape, glue and composite.It has the following several parts: the electrical system, rolling system, oven drying system, tape, glue system running deviation correction system (group 2), nylon film base adhesive composite system, tape, PE film and display system and components, such as embryo winding system optional added starched system, industrial cloth.

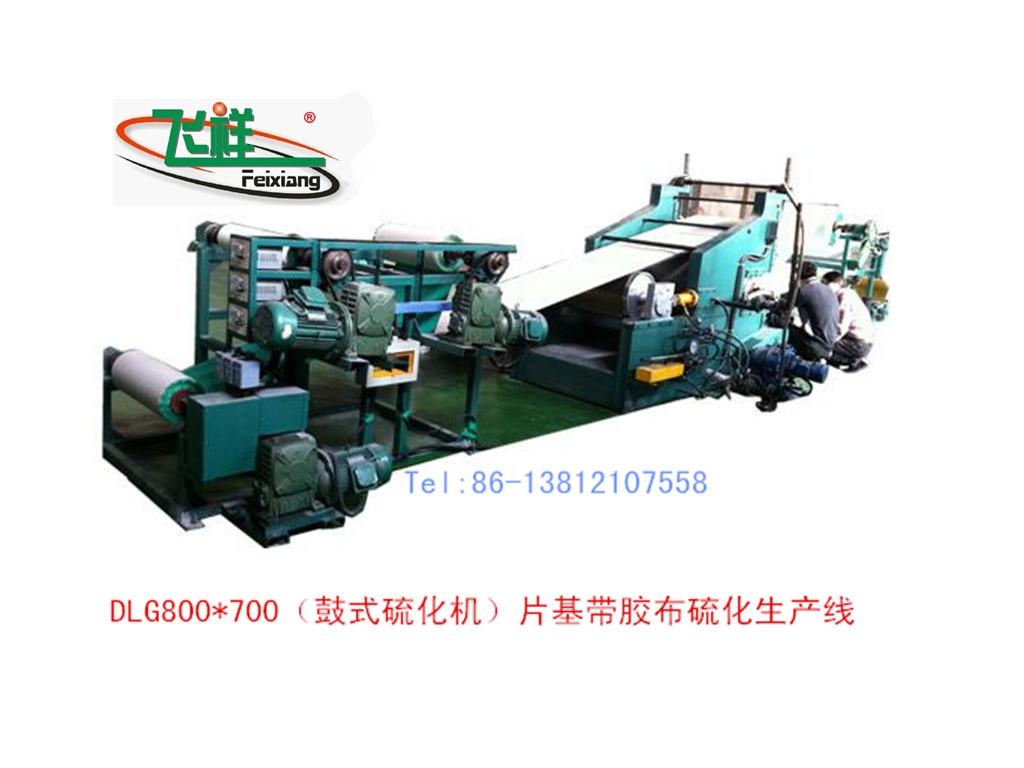

3). QZD650-16 type automatic production line for nylon belt drum vulcanizing cooling---Is company in order to meet the market demand, according to baseband process characteristics after years of research and development, in 2016 successfully developed new technology, new craft, production volumes are nylon baseband dedicated equipment.

equipment has the following characteristics:

(1) The production line a high degree of automation, with continuous coating, drying, compound, heating, cooling, rolling, winding;

(2)Pressure in a state of continuous hot press vulcanization and at the same time pressure in a state of continuous cooling chip baseband belt body;Products high surface smoothness;

(3) mounted (floor) reduction drive systems, infinitely adjustable-speed, transmitting torque, cover an area of an area small;

(4) auxiliary magnetic powder brake friction ring or rolling;Winding adopts torque motor winding, tension control adjustment.

4). JT type automatic splicer------Is a new type of pneumatic or hydraulic system fully automatic splicer, equipment with water cooling system, hot plate for aluminum alloy material, used in the production of various rubber products and thermosetting plastic bakelite products, light conveyor belt, nylon is baseband connector cementing ideal equipment, high production efficiency.