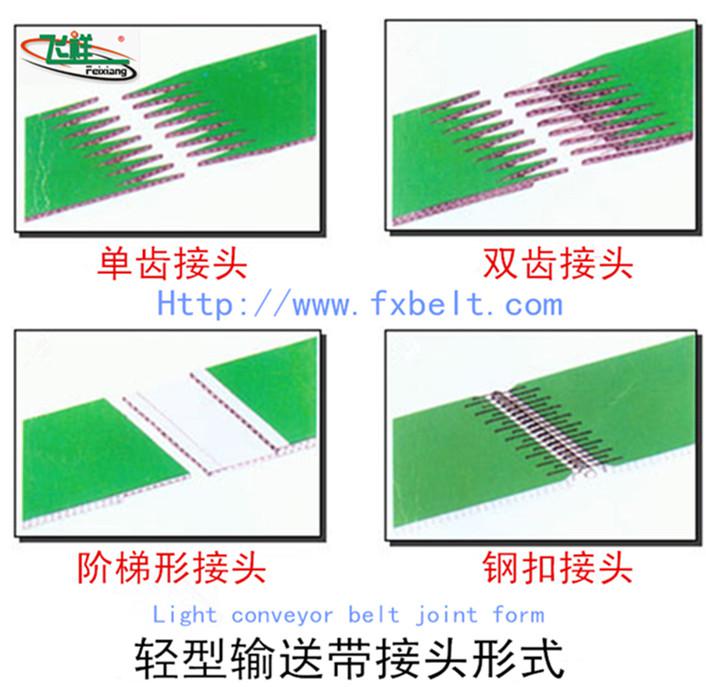

1 Light conveyor belt joint way generally has the following three kinds of steel joint, namely cold glued joints and hot pressing vulcanization joint.

Steel buckle joint is refers to the use of belt buckle joint, the joint method is convenient and quick, also compares the economy, but the low efficiency of joint, easy to damage, had certain influence on the service life of conveyor belt products.

Cold glued with conveyor belt special adhesive glue joint in rubber conveyor belt, PVC and PVG whole core antistatic properties are frequently used in the conveyer belt joint, commonly used in circular conveyor belt installation is convenient.Cold sticky glue joint is to adopt the way of adhesive joint.This method is more efficient than steel buckle joint, simple, economic, coupling effect is good, but in the process of conveyor belt running vulnerable to highlight parts of the conveyor floor scratches, and lead to joint tear, damage to the connector, connector cementing conveyor belt running direction should be paid attention to;In addition the quality of the adhesive joint impact is very big.

2 Heating vulcanization joint is one of the most ideal method of joint guarantee high coupling effect, long service life.Is product process, high cost and trouble joint operation time is long.Trapezoidal connection commonly used rubber belt, PVC belt generally USES tooth connection.

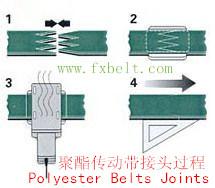

(1). The belt joint method:Nylon belt joint method generally USES step two head and stepped inclined joint directly, adopt heat vulcanization connect way.

(2). Polyester belt, PU synchronous belt is generally use tooth hot way.

Su ICP for the record:

苏ICP备11045486号

Su ICP for the record:

苏ICP备11045486号